I’ve been working on a phone holder for a car that sits in a cup holder. The reason for this is that I don’t like things blocking my view when I’m driving. Thus, I want to ‘move’ the phone away from the windscreen and down towards the centre console.

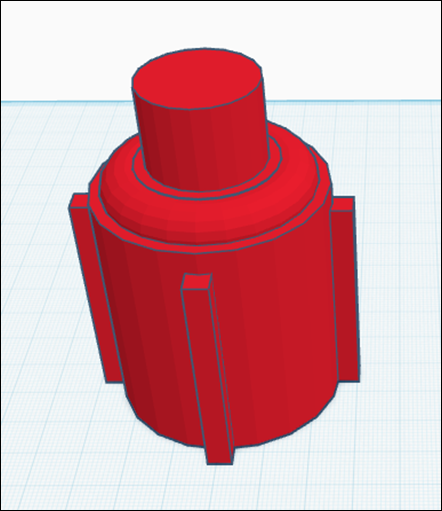

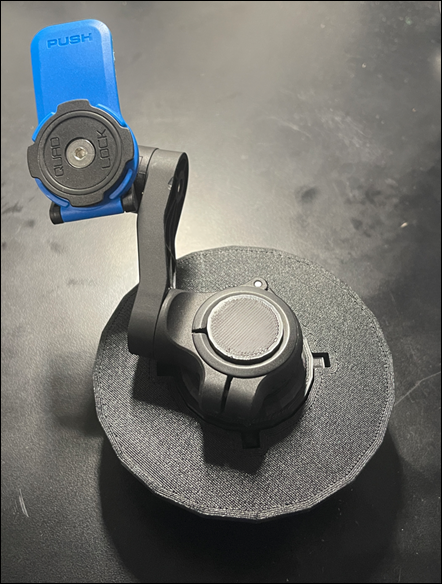

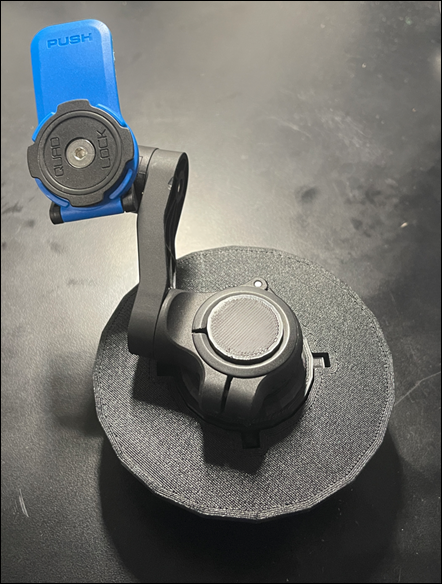

Rather than completely re-inventing the wheel here, I decided to use a motorcycle mount from Quadlock to actually hold the phone. The other end needed to grip onto something like a tube.

The starting point for mounting the Quadlock was to create something that would sit in the cup holder and then attach to the Quadlock. Creating a solution to do that is easy enough, but the challenge comes when trying to print that.

Why? Because, basically you can’t print in thin air. You need each layer of the print to be supported but something underneath it. This means you have to think carefully about your design.

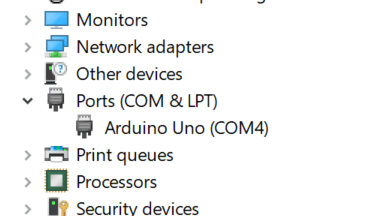

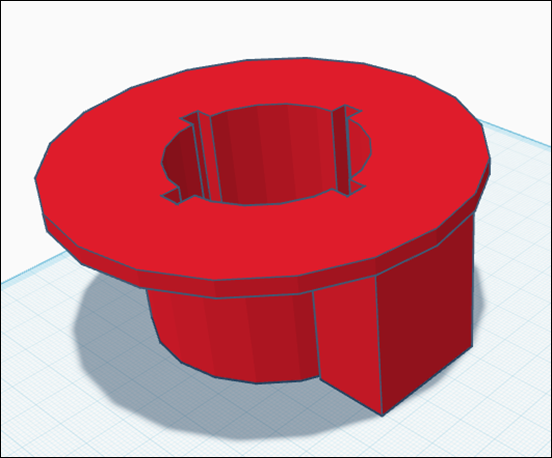

What I ended up doing was splitting the mount into two parts. The first part, as you see above, fits inside the cupholder in the car. That means basically using a cylinder design. However, to stop this rotating in car’s cupholder I added a key since the cupholder has a bridge to another holder nearby.

I then put a table top onto the cylinder to stop the structure tipping side to side and potentially jumping out of the holder in the car. This is where I had to start thinking about how I was going to print this because, in the long run, there would need to be a structure on the top of the table to connect to the Quadlock, but if I made it a single object to print I’d have trouble printing it as much of it wouldn’t have support during printing.

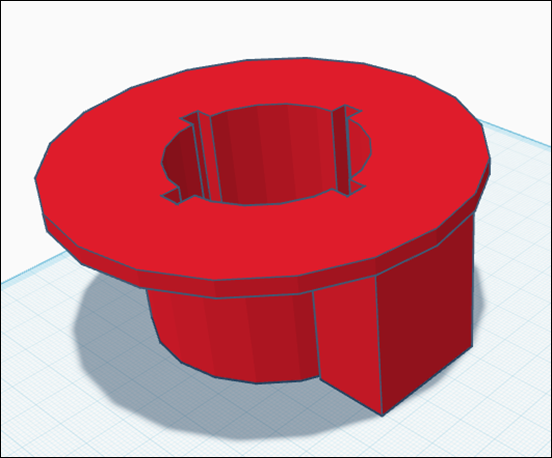

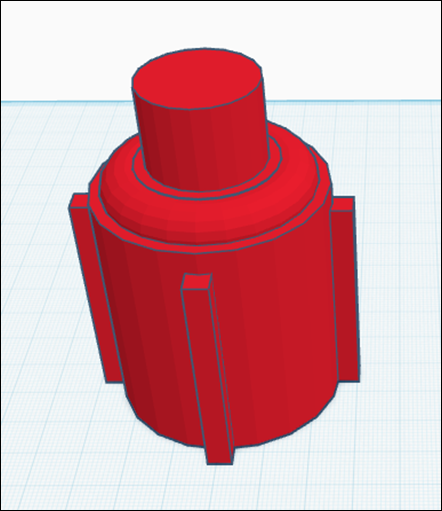

So, I broke the holder in two pieces, the insert with the table top (above), that I could flip and easily print and have everything supported and then an insert (below) to hold the Quadlock and slide inside the holder.

If I had tried to print these tow items as a combined object I would have struggled. But breaking them into two separate interlocking parts allows both to have full support when printed.

You will also notice that I added four key slots for the insert to prevent it from rotating when in the printed holder. The Quadlock then securely fastens to the cylinder at the top of the insert.

The end result looks like the above and works well. The tabletop of the holder also prevents the Quadlock from scratching the trim if it does move around when the car is travelling. It also takes some weight off the cylinder that mounts the Quadlock as well reducing the chance of it snapping when the car is in motion as the phone bounces around.

The key is that, not only do you need to design an object to solve your problem but you need to work out a way to print it using a 3D printer that can’t print on just thin air!