After taking a good while to get the robot arm assembled, the next challenge was hooking it up and doing some initial testing.

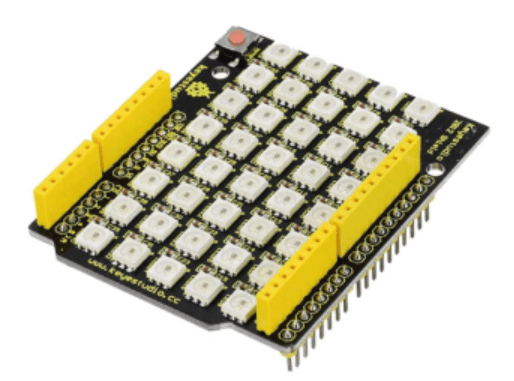

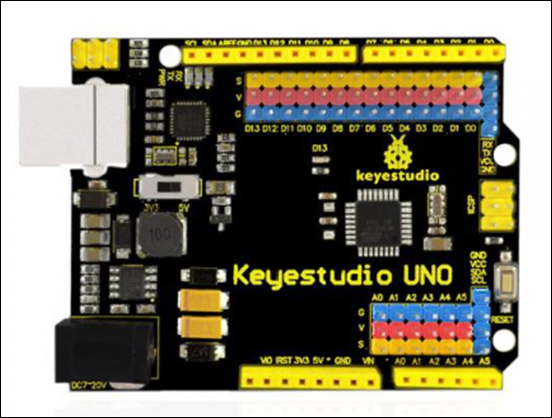

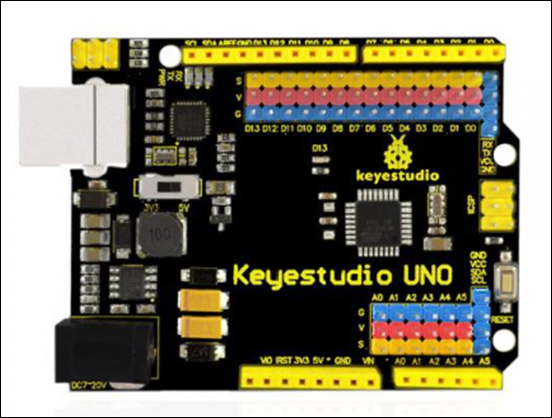

To control the arm I had invested in a

KEYESTUDIO UNO R3 Development Board For Arduino Official Upgrated Version With Pin Header Interface

This is the same board that is used on the Sun follower kit I recently built. I like this board because it has all the connections for each port already mounted on the board. It also has the GND and VCC for each port as well making it easy to plug standard connectors into it. Less soldering, in my case , means less problems or stuff ups by me!

The first issue I discovered was that many of the leads to the servos were too short when the servo moves the arm through its full motion. In one case I threw the controller board off the table. Thus I needed to invest in:

Servo extension cable 600mm

and

Servo Extension Cable (1m)

to allow full movement of the arm.

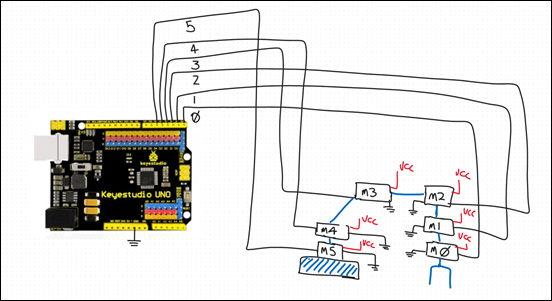

The next challenge I found was when I moved on from testing each servo individually to testing the arm as single unit, some of the servos didn’t seem to work! Another oversight by me upon further investigation. The controller board has enough power to run a single servo but not a bank of servos all together from the VCC rails on the controller board.

I therefore connected the VCC of the all the servos directly to my bench top power supply to give it the juice needed. Interestingly, during testing I have seen the arm draw well over 1 amp in total from the power supply as various servos operate. Clearly, no way the controller board could provide that by itself.

With all the servo motors now working, I started to try and get the arm to move to a location and pick up an item. After a while, servo 0 (gripper) stopped working?? I checked all the connections and it still wasn’t working. It wasn’t until I actually touched the servo and found that it was super hot that I realised I must have burnt it out. Damm.

I replaced the burnt out servo with another I had. I also attempted to fix the burnt out servo by opening it up to see if I could free things up inside, but that didn’t go well and I ended up with the internals of the servo motor all over the floor.

I also learnt that when power is removed from the servos, for example when re-flashing the controller board, the servos don’t hold the arm in place. This means that when power is removed from the servos the arm collapses under its own weight. This can cause some unexpected impacts with the environment when power is restored. I’ll need to think about how to solve this down the track but for now I simply support the arm when I flash the controller with updated code.

Finally, with a replacement servo for the gripper and motor extension cables I had the arm operational to a point where I could start getting it to do something interesting.

I’ll cover off the code development in an upcoming article and hopefully also provide some videos of the arm in operation.